|

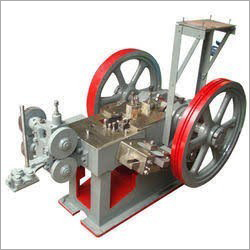

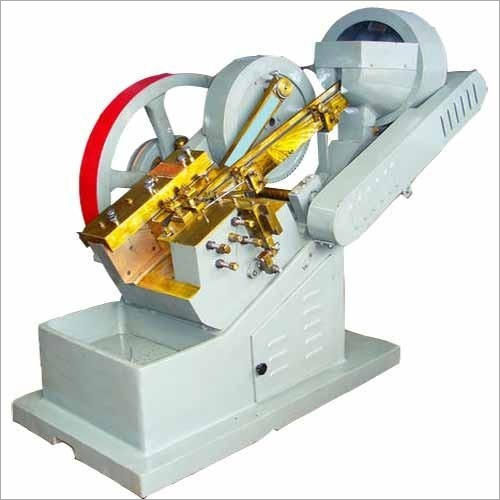

Vertical Thread Rolling Machines

Product Details:

- Type Thread Rolling Machine

- Material Cast Iron, Mild Steel

- Automatic Grade Automatic

- Control System PLC Control

- Voltage 440 Volt (v)

- Click to View more

Vertical Thread Rolling Machines Price And Quantity

- 240000.00 INR/Piece

- 1 Unit

Vertical Thread Rolling Machines Product Specifications

- Thread Rolling Machine

- 440 Volt (v)

- Cast Iron, Mild Steel

- Automatic

- PLC Control

Vertical Thread Rolling Machines Trade Information

- 15 Unit Per Month

- 1 Months

- Loose Packing

- All India

Product Description

Vertical Thread Rolling Machines are specialized equipment used in the manufacturing process of rolling threads on cylindrical workpieces, such as bolts, screws, and other threaded fasteners. These machines are designed to form threads by applying pressure with hardened dies, which deform the material (usually steel or another metal) into the desired thread shape without cutting. This results in stronger, more durable threads compared to traditional machining methods.

Key Features and Description:

Vertical Design: Unlike horizontal thread rolling machines, the vertical configuration offers better space utilization and ease of loading and unloading the workpieces. The vertical orientation also allows for better gravity assistance in feeding the material.

Thread Rolling Process: In the vertical thread rolling process, two hardened dies are mounted vertically, and the workpiece is placed between them. The dies rotate and apply pressure, causing the material to flow and form the thread profile. The process is highly efficient for mass production of threaded components.

Die Selection: The dies used in these machines are typically made from high-quality tool steel or carbide, offering long-lasting durability and precision in thread formation. The dies can be customized based on the required thread pitch, size, and shape.

High Precision and Strength: Vertical thread rolling machines offer high precision, producing threads that are smooth, accurate, and free of defects. Additionally, the cold forming process results in threads with improved tensile strength and resistance to wear, which is critical for many industrial applications.

Automation and Control: Many modern vertical thread rolling machines feature automated systems for feeding, positioning, and controlling the rolling process. These systems can monitor parameters like speed, pressure, and alignment, ensuring consistent results across large production runs.

Applications: Vertical thread rolling machines are commonly used in industries such as automotive, aerospace, construction, and manufacturing, where high-strength, precision-threaded fasteners are required. They are ideal for mass production of bolts, screws, studs, and other threaded components.

Benefits:

Increased productivity due to faster processing times compared to cutting methods.

Improved thread quality with fewer defects.

Higher strength in the threads due to the cold forming process, which creates a more uniform grain structure.

Reduced material wastage since no material is cut away in the process.

Less heat generation, contributing to a longer tool life.

Safety Features: Modern machines often come equipped with safety mechanisms, including automatic shutdowns, guards, and sensors, to ensure the protection of operators.

In summary, vertical thread rolling machines are a vital tool in producing high-strength, precision threaded components efficiently, particularly for high-volume production. Their ability to form threads without cutting the material results in stronger threads and better material utilization.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Thread Rolling Machine' category

|

PALI MACHINE TOOLS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |